Vehicle performance is the study of the motion of a vehicle. The motion of any vehicle depends upon all the forces and moments that act upon it. These forces and moments, for the most part are caused by interaction of the vehicle with the surrounding medium(s) such as air or water (e.g. fluid static and dynamic forces), gravitational attraction (gravity forces), Earth’s surface (support, ground, or landing gear forces), and on-board energy consuming devices such as rocket, turbojet, piston engine and propellers (propulsion forces). Consequently, in order to fully understand the performance problem, it is necessary to study and, in some way, characterize these interacting forces.

How To Build An Electric Vehicle?

Disruption in the Automotive and Transportation industry is well under way. How we get from Point A to Point B is being reinvented due to increasing urbanization. This is driving the convergence of autonomous, electrification, connectivity and shared transportation systems rapidly. Auto OEMs and suppliers have to develop and execute new business models to prevent becoming obsolete as these mega trends unfold and technology innovation increases exponentially. The race is on for Auto OEM’s and suppliers to transform their business and provide multimodal mobility services for the future of mobility.

Simcenter Simulation: The Key to Make Safe Autonomous Vehicles

As vehicles become more automated with advanced driver assistance systems (ADAS), development and validation testing conditions need to be defined. Which scenarios should be considered for ADAS and future autonomous vehicles (AVs)? How can a large number of potential driving situations be considered and how can the most critical ones be identified? Can verification and validation (V&V) be managed in a realistic timeframe and at an acceptable cost? This blog post highlights a process applied during vehicle development, and discusses the support Siemens Digital Industries Software and ETS Solutions Asia engineering services team can provide.

What is Industry 4.0 in terms of Manufacturing, the innovations and trends

By its nature, an Industry 4.0 implementation will be incremental, not big bang. Manufacturing will still need people and centralized information applications in addition to the new IIoT data for the next several decades. That’s where the systems that manage all that data, and the people, processes, products and machines that generate it – manufacturing operations management (MOM), or the next evolution of manufacturing execution systems (MES) – will play a critical role.

Noise and Vibration Monitoring Guidelines

Noise and vibration are both dynamic processes and have a close physical relationship. Vibrating systems make noise, and noise makes structural systems vibrate. Both noise and vibration are adversely affecting people and if sufficiently intense, both noise and vibration can permanently hurt people. At the same time, also structural systems, if excited by excessive noise and vibration over sufficient periods of time, can fatigue and fail.

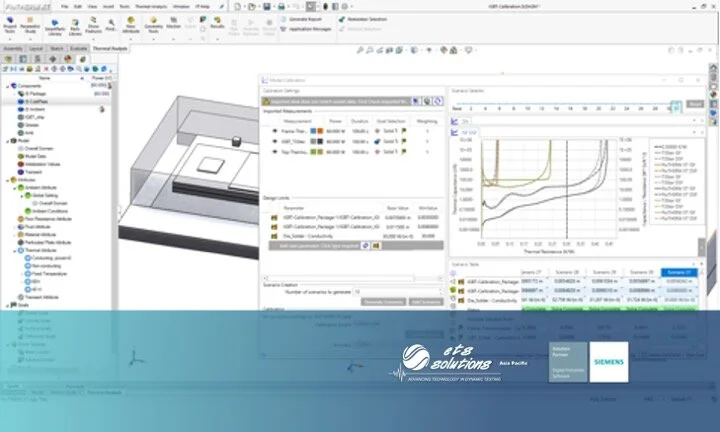

Automatic Thermal Model Calibration

What are transient thermal measurements and structure functions, their advantages, and how we use them tcalibrate and improve our semiconductor thermal models, Simcenter Flotherm is a unique combined test and simulation solution for automatic calibration of semiconductor package thermal models that maximizes simulation accuracy. This helps engineers to better optimize electronics thermal design for reliability, reducing field failures, and to reduce overdesign-linked costs.

Structural Dynamics Testing Made Easy with Simcenter

Simcenter solutions offer an integrated approach to test preparation, modal testing, modal analysis, numerical model correlation, model updating, and model use. from impact testing on small structures to large scale campaigns using hundreds of measurement channels, puts a tradition of cutting-edge expertise at your fingertips as you maximize testing efficiency.

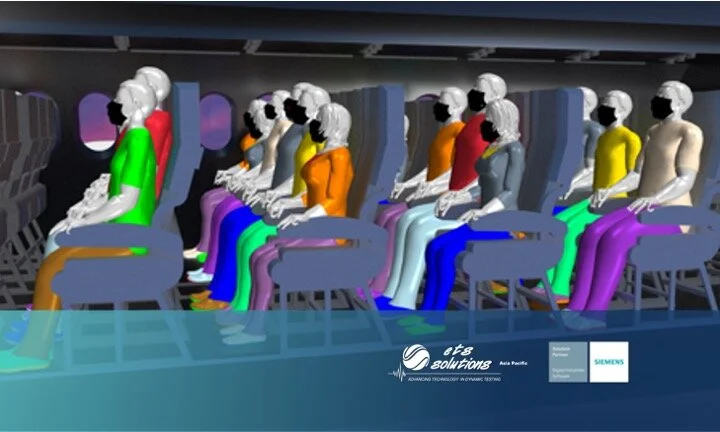

Cough Simulation in an Aircraft Cabin

Every human being is innately different and so is our cough. 7.5 billion people. 7.5 billion different coughs. There’s been plenty of research into the human cough. Enough, in fact, to tell us what an average cough from an adult should look like. It’s this average cough that’ll help us uncover some key insights behind how cough droplets travel and move in an aircraft cabin.

Simcenter Testlab: Significantly Reduce Aircraft Noise

Simcenter Testlab Interior Sound Source Localization is a complete solution for quick and accurate identification and ranking of sound sources in highly complex interiors. Siemens Digital Industries Software has designed a number of cutting edge sound source localization solutions to increase overall testing productivity. Finding the root cause of noise through transfer path analysis helps you identify the main sound sources and transfer paths, both airborne and structure- borne.

Optimize Thermal Performance of Power Adapters with Simcenter Flotherm

In the case of the power adapters that NXP Semiconductors’ Smart Power Division are developing thermal considerations have really come to the fore, driven by the trends we see in mobile power adaptors, which are getting smaller and have a higher output power. Thermal limits are now constraining all aspects of the design.

Karma Automotive: Excellence NVH Performance with Simcenter

Karma Automotive established a strategic partnership with Simcenter Engineering and Consulting services to meet NVH performance targets and implement state-of-the-art NVH testing and simulation processes. Simcenter™ software uniquely combines system simulation, 3D CAE and test to help you predict performance across all critical attributes earlier and throughout the entire product lifecycle.

The Importance of Junction Temperature in Electronics Components Thermal Reliability

John Wilson, technical marketing engineer at Mentor, a Siemens Business, explains how junction temperatures have a direct correlation to product reliability and performance. Using tools such as Simcenter™ T3STER™ and Simcenter™ Flotherm™ enable users to tackle the challenge of designing for reliability without the need for prototyping.

Simcenter Flotherm - accurate simulations for electronics thermal design

Simcenter Flotherm - The goal of electronics thermal design is to accurately predict component junction temperatures to ensure that they are within specification. CFD allowed designers to predict the flow of cooling air, and include 3D thermal simulations of the board and components, increasing the need for more accurate component level modeling.

Electric Vehicle Manufacturer Moves Quickly with Simcenter and NX

Revolutionizing productivity, Electra Meccanica moved quickly, transforming a napkin sketch into a digital NX™ software design in a matter of days, then using Simcenter™ software to optimize and validate the performance of the all-electric SOLO. Finally, using NX CAM and 3D printing, Electra Meccanica built its dream car.

Simcenter Help Facebook to significantly improve its new server design and achieve thermal efficiency

For its first datacenter in Prineville, Oregon, Facebook set out to significantly improve its power efficiency, cost, reliability, serviceability and environmental footprint. To this end, a holistic approach was used to redesign many dimensions of the datacenter and servers. This white paper1 focuses on the Facebook server design, combining aspects of power, motherboard, thermal and mechanical design.

Is your electronics cooling software fit for purpose?

More than just a CFD code, STAR-CCM+ is a complete multiphysics toolbox, able to solve flow, thermal and stress problems involving multiple phases. From liquid jets, to water ingression, STAR-CCM+ allows you to simulate any cooling strategy that you can define and even the effect of what happens when those strategies go wrong.

Finding the longest lasting design faster

The first is a hybrid approach, integrating test and simulation for realistic road-load prediction, even for loads that cannot be measured. And the second is a digital road approach, running a comprehensive virtual model on a digital track when test data is unavailable. Additionally, it considers new emerging technologies, such as composites and additive manufacturing.

Simcenter 3D for additive manufacturing simulation - Print right the first time

Additive manufacturing (AM) is changing the way products are made. New revolutionary machines and processes are rapidly pushing AM from the prototype environment onto the production floor. The additive manufacturing capabilities in Simcenter 3D software are used to predict distortions and defects before parts are printed, thereby reducing the number of test prints and improving the quality of the final print.