Using Simcenter Amesim™ software, Simcenter Engineering experts and Honda set out to develop a new prediction technique and a new evaluation method for engine restart vibrations. Honda can now accurately predict the entire powertrain restart process, beginning with the vehicle controls signals causing a certain in-cylinder pressure, which then results into driveline torque, particular suspension and powertrain bushing interface forces and eventually body vibration shock.

Karma Automotive Resurrects Iconic Electric Vehicle Using Siemens Solutions

One of these startups is Karma Automotive, a California-based carmaker that rose from the ashes (or rather assets) of Fisker Automotive in 2014. In the resurrection process, Karma managed to preserve the good and overcome the bad: they retained the beautiful Italian design of their cars, which held a lot of appeal to their customers, but significantly upgraded the technology. The result is a luxury electric hybrid sedan that maintains much of the original exterior and interior of the Fisker Karma, but incorporates an A123 battery, charger and electrical controls. It is “the car you drive when you want to be seen,” says Bob Kruse, chief technical officer of Karma Automotive.

NASA’s $10 Billion James Webb Space Telescope Fully Fueled For Launch

The world’s largest and most powerful space science telescope is finally scheduled for launch, on Christmas Eve. The James Webb Space Telescope (JWST) has been in the works for decades, and its gold-plated, 21-foot mirror is capable of exploring much farther out into space than its predecessor, the famous Hubble Space Telescope. After many delays and years of waiting, for many, it seems almost unbelievable that it’s finally about to happen.

Leave Your Status Quo, Accelerate Durability Testing

The same applies for durability engineers. Technology evolves so quickly that holding on to traditional processes and methodologies actually equals standing still. I hear you thinking: “I’m doing well, my business is stable.” But can you keep up? Your customers are getting more demanding, and your competitors are always close. It requires an effort to keep moving forward, innovate, and search new solutions or methodologies. But it pays off!

The Fast And The Obvious – Battery Pack Thermal Simulation

Today, vehicle electrification represents one of the major pillars to help reduce the overall greenhouse gas emissions from human activity. From the early days, there’s been a lot of effort to reduce the overall cost of the battery pack and increase its energy density. Above all, this was essential to offer commercially competitive electric vehicles (xEVs), compared to conventional internal combustion engine (ICE)-based vehicles. It was critical to reduce the consumer’s range anxiety, or in simple terms, remove the fear of being flat in the middle of the Mojave Desert.

Black, Gray, Blue, Purple, or Green - What Color Is Our Low Carbon Hydrogen Future?

Hydrogen is the most abundant chemical substance in the universe, constituting roughly 75% of all normal matter. Our own sun is 75% Hydrogen and 25% helium. Hydrogen is about three times as energy-dense as natural gas (which is principally methane) and more than twice as energy-dense as gasoline. Burning hydrogen is much cleaner than burning hydrocarbons. When mixed with pure oxygen it only produces water as a by-product of combustion.

Ensure The Safety of Hydrogen Mobility

Mobility electrification is not a trend. It is a fact. Most OEMs are already planning the retirement of their combustion-engine fleets. But with electrification we generally associate Li-ion batteries and a lot of inherent challenges. Rare materials, range anxiety, lack of charging stations, battery safety, poor recycling possibilities are some of them. Although extensive research is being conducted to solve these challenges, an alternative is being considered: hydrogen fuel cell vehicles. In this article we discuss how simulation can help OEMs & suppliers virtually design and certify the composite pressure vessel used for hydrogen storage.

Vehicle Performance Engineering

Vehicle performance is the study of the motion of a vehicle. The motion of any vehicle depends upon all the forces and moments that act upon it. These forces and moments, for the most part are caused by interaction of the vehicle with the surrounding medium(s) such as air or water (e.g. fluid static and dynamic forces), gravitational attraction (gravity forces), Earth’s surface (support, ground, or landing gear forces), and on-board energy consuming devices such as rocket, turbojet, piston engine and propellers (propulsion forces). Consequently, in order to fully understand the performance problem, it is necessary to study and, in some way, characterize these interacting forces.

How To Build An Electric Vehicle?

Disruption in the Automotive and Transportation industry is well under way. How we get from Point A to Point B is being reinvented due to increasing urbanization. This is driving the convergence of autonomous, electrification, connectivity and shared transportation systems rapidly. Auto OEMs and suppliers have to develop and execute new business models to prevent becoming obsolete as these mega trends unfold and technology innovation increases exponentially. The race is on for Auto OEM’s and suppliers to transform their business and provide multimodal mobility services for the future of mobility.

Simcenter Simulation: The Key to Make Safe Autonomous Vehicles

As vehicles become more automated with advanced driver assistance systems (ADAS), development and validation testing conditions need to be defined. Which scenarios should be considered for ADAS and future autonomous vehicles (AVs)? How can a large number of potential driving situations be considered and how can the most critical ones be identified? Can verification and validation (V&V) be managed in a realistic timeframe and at an acceptable cost? This blog post highlights a process applied during vehicle development, and discusses the support Siemens Digital Industries Software and ETS Solutions Asia engineering services team can provide.

Battery Temperature Test Chamber

Different environmental conditions such as extreme heat, extreme cold, moisture or other variables can influence a device failure in various ways. In today’s world, we all expect fault-free products and uninterrupted operations and services and in order to guarantee 100% performance, manufacturers from various industries must conduct environmental simulation tests of their products.

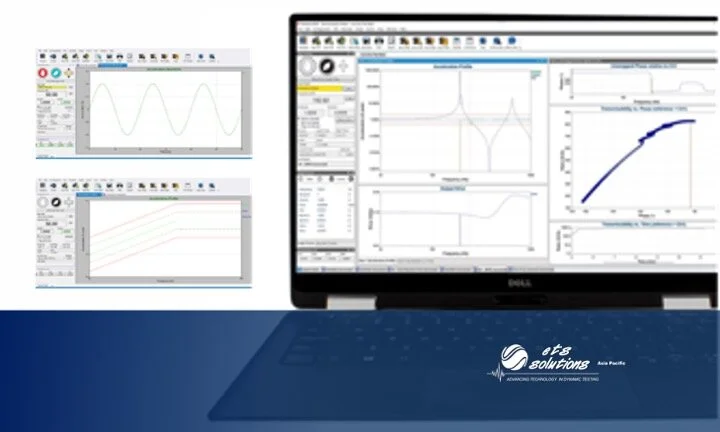

Sine Vibration Testing

Sine Vibration Testing may be considered as the most basic vibration testing method used. This type of vibration testing requires less complex parameters compare to other type of vibration testing. Knowing the nature of sinusoidal signal, makes this type of vibration testing easier to understand and to get familiar with. Though, easier to understand does not make it less important compare to other type of vibration testing. Sine vibration testing may still be at the top rank when we are thinking of dynamic characteristic measurement.

Karma Automotive: Excellence NVH Performance with Simcenter

Karma Automotive established a strategic partnership with Simcenter Engineering and Consulting services to meet NVH performance targets and implement state-of-the-art NVH testing and simulation processes. Simcenter™ software uniquely combines system simulation, 3D CAE and test to help you predict performance across all critical attributes earlier and throughout the entire product lifecycle.

Electric Vehicle Manufacturer Moves Quickly with Simcenter and NX

Revolutionizing productivity, Electra Meccanica moved quickly, transforming a napkin sketch into a digital NX™ software design in a matter of days, then using Simcenter™ software to optimize and validate the performance of the all-electric SOLO. Finally, using NX CAM and 3D printing, Electra Meccanica built its dream car.

Finding the longest lasting design faster

The first is a hybrid approach, integrating test and simulation for realistic road-load prediction, even for loads that cannot be measured. And the second is a digital road approach, running a comprehensive virtual model on a digital track when test data is unavailable. Additionally, it considers new emerging technologies, such as composites and additive manufacturing.

Test based durability engineering for Automotive and Transportation

Make Autonomous Vehicles Safe - White Paper

Addressing complex engineering challenges by enhancing simulation efficiency

Computer-aided engineering (CAE) has long proven its value as a troubleshooting and analysis tool, but is generally perceived as slow, delivering accurate results too late to drive development. The simulation process with traditional CAE tools is slow due to tedious geometry cleanup processes, and simulation disciplines are disconnected from each other, hampering efficient workflows.

Counter Measuring Product Durability Issue by Evaluating Structural Dynamic Characteristic

In such industry that is facing tough market competition like automotive industry, having product durability issue during prototype testing and validation stage will be quite challenging, or sometime even quite frustrating. Especially when you are the testing engineer or project manager that has to ensure that all prototype testing and validation is done within the schedule.