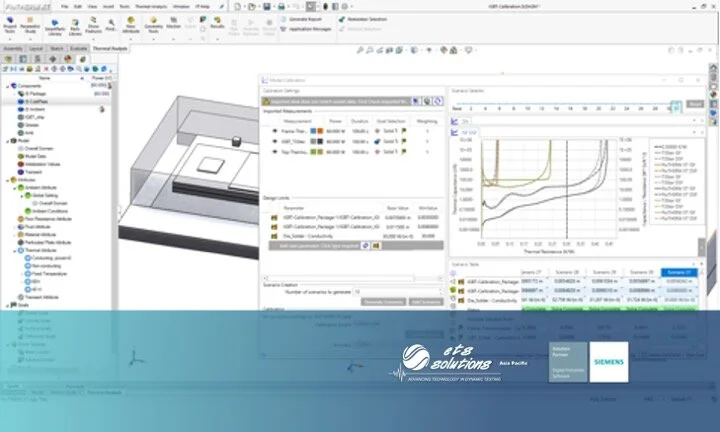

What are transient thermal measurements and structure functions, their advantages, and how we use them tcalibrate and improve our semiconductor thermal models, Simcenter Flotherm is a unique combined test and simulation solution for automatic calibration of semiconductor package thermal models that maximizes simulation accuracy. This helps engineers to better optimize electronics thermal design for reliability, reducing field failures, and to reduce overdesign-linked costs.

Optimize Thermal Performance of Power Adapters with Simcenter Flotherm

In the case of the power adapters that NXP Semiconductors’ Smart Power Division are developing thermal considerations have really come to the fore, driven by the trends we see in mobile power adaptors, which are getting smaller and have a higher output power. Thermal limits are now constraining all aspects of the design.

The Importance of Junction Temperature in Electronics Components Thermal Reliability

John Wilson, technical marketing engineer at Mentor, a Siemens Business, explains how junction temperatures have a direct correlation to product reliability and performance. Using tools such as Simcenter™ T3STER™ and Simcenter™ Flotherm™ enable users to tackle the challenge of designing for reliability without the need for prototyping.

Simcenter Flotherm - accurate simulations for electronics thermal design

Simcenter Flotherm - The goal of electronics thermal design is to accurately predict component junction temperatures to ensure that they are within specification. CFD allowed designers to predict the flow of cooling air, and include 3D thermal simulations of the board and components, increasing the need for more accurate component level modeling.

Simcenter Help Facebook to significantly improve its new server design and achieve thermal efficiency

For its first datacenter in Prineville, Oregon, Facebook set out to significantly improve its power efficiency, cost, reliability, serviceability and environmental footprint. To this end, a holistic approach was used to redesign many dimensions of the datacenter and servers. This white paper1 focuses on the Facebook server design, combining aspects of power, motherboard, thermal and mechanical design.