Image/Siemens: Durability Testing

If you are new to the topic of test based durability engineering in Automotive and Transportation industry let’s start with a few durability fundamentals that introduces the base concepts, terminology and essential engineering insights to know.

What is durability?

Durability is the ability of a vehicle to perform its function long-lasting and repeatedly. It is a quality feature. Think for example of a car driving 300 000 km, or a truck hitting the road for > 1 000 000 km.

Image/Siemens: Durability Testing

What is fatigue?

The underlying physical phenomena causing components to fail is (metal) fatigue. Fatigue is a progressive failure phenomena associated with the initiation and propagation of cracks to an unstable size.

Image/Google: Fatigue Testing

Which parameters influence fatigue?

Engineers involved into durability engineering need to understand three key factors determining fatigue: loads, geometry and material.

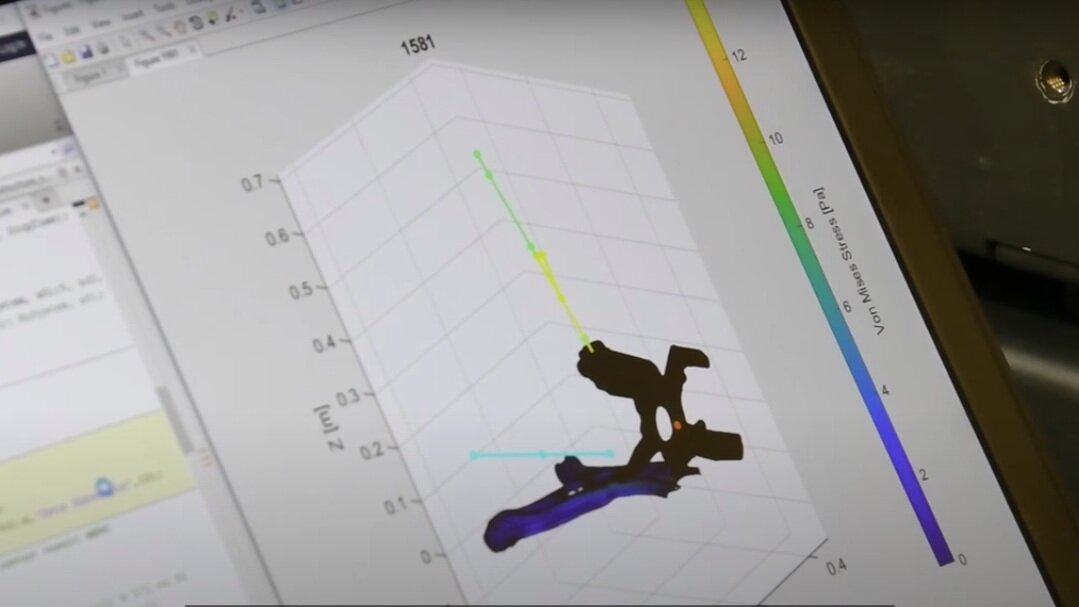

What is RLDA?

Road load data acquisition (RLDA) is a test method for measuring the precise vehicle loads either on public roads or on proving grounds by replicating specific driving profiles. This vital load information is key input for downstream computer aided engineering (CAE) and laboratory testing activities.

[Simceneter] Understanding Loads - RLDA

Why are loads important?

For a standard steel component, a 10% change on load amplitude reduces the life with a factor of 2. It is therefore very important to understand customer loading (roads, driving styles, vehicle loading....)

Image/Google: Potholes Roads

Why accelerated testing (and simulation)?

It takes a lot of repetitions (cycles) – read time - to validate durability performance. Time which simply is not available. Accelerated test and simulation methods (on proving grounds, on laboratory test rigs and using simulation (virtual tests)) are needed.

Why Test based durability engineering?

In the Automotive and Transportation industry consumers are increasingly demanding these days: a wide choice in models, increased fuel economy, great design, ultimate comfort, extended mileage and a long product life span. The mind-set governing this wish list does not allow for compromise on either durability or reliability.

Long-term quality, competitive pressure and emerging markets continue to heavily impact the Automotive and Transportation industry. Customer expectations for long-term quality and high mileage are increasing. Durability is strongly related to brand image and thus a crucial selling point. Competitive pressure forces companies to bring to market ever more design variants in an ever shorter time. Last but not least the emerging markets are the key source of growth for today’s global automotive industry.

To guarantee durable designs and avoid excessive product recalls vehicle durability testing is an integral part of vehicle development. To reduce time to market from concept to start-of-production there is a continuous need to shorten the vehicle development cycle. Durability testing teams need to account for geographical differences in customer preferences and product requirements.

Despite the growing use of simulation, durability engineering departments in the Automotive and Transportation industry are facing an ever-growing and challenging volume of testing work. Innovative tools are needed for both (road) load data acquisition and processing.

[Simcenter Testing] Durability DAQ for hybrid vehicle battery unit

Our solution?

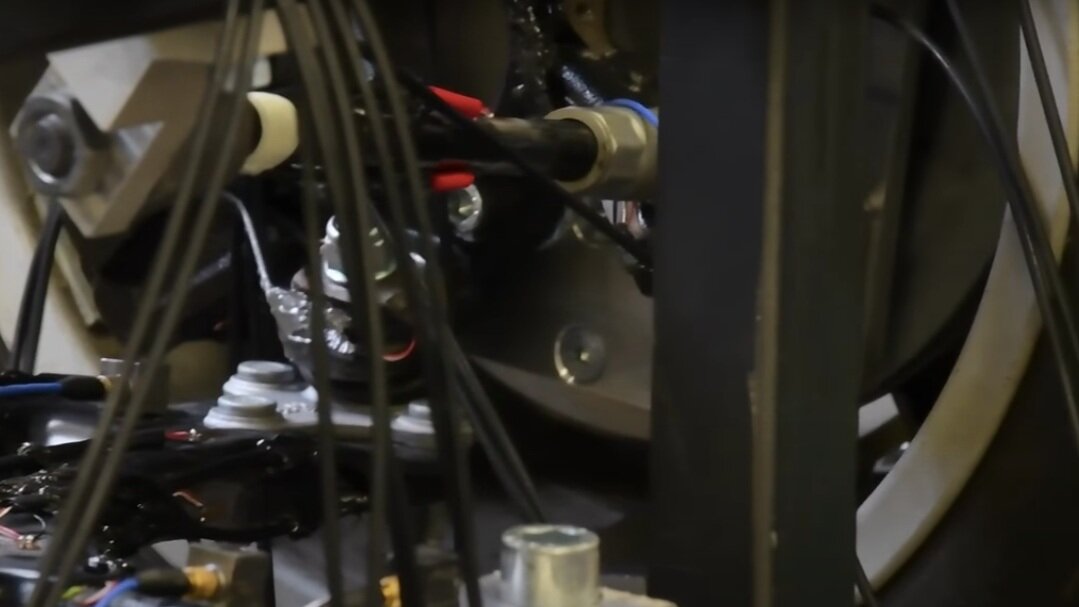

A complete, integrated, end-to-end hardware and software solution dedicated to (road) load data acquisition and (road) load data processing which helps to maximize productivity of test campaigns on proving grounds and road simulators, performs campaigns in complete confidence, maps (local) customer usage to (global) condensed test scenario and ultimately achieves a higher return on investment from existing testing facilities.

The Simcenter SCADAS hardware and Simcenter Testlab software suite are the ideal companions for accurate (road) load data acquisition. Simcenter Tecware software complements this portfolio with an integrated approach to (durability) data analysis, allowing for flexible target setting as well as precise and accelerated test schedule definition.

Image/Siemens: The Simcenter SCADAS hardware and Simcenter Testlab software

If you are struggling with below problems:

Access to real-life and accurate vehicle loads directly impacting lifetime of a product with timely delivery of large amounts of high-quality data.

Shortened development cycles by accelerated testing to speed up physical validation of new designs.

Adaptation of product requirements based on vehicle usage data (roads, driving habits, vehicle usage)

The below are the operational benefits our durability testing solutions deliver:

Complete, integrated, end-to-end hardware and software solution dedicated to road load data acquisition, analysis and reporting

Maximize productivity and output of test campaigns on proving grounds and road. Optimize every single step of the test and analysis process: faster instrumentation, increased uptime, right-first-time tests, faster analysis and quicker results delivery.

Perform test campaigns in complete confidence and automate repetitive analysis tasks maintaining utmost quality

Accelerated and realistic durability test schedules derived from advanced load analysis technology which maps (local) customer usage to (global) condensed durability test scenario

Achieve a higher return on investment from testing facilities and reduce overall costs by reducing hardware investments, optimizing number of software tools and minimizing training

Valuable insights, reliable test data, faster analysis, work smarter, accelerated tests, realistic tests, quicker delivery, optimize software investment.

Simcenter durability solutions are not limited to testing solutions only.

Simcenter offers fully integrated durability testing and simulation solutions for the transportation industry.

Through innovative hard-and software applications, Simcenter provides expertise at the concept, design and validation stages of the vehicle development process along with a complete portfolio of testing solutions, embedded simulation techniques and engineering services, thus ensuring a more (cost)-effective engineering process.

The right vehicle, with the right durability performance, at the right time.