The customer is a world-leading technology company. It researches and develops solutions for safety, environmental protection and networking, in order to keep developing mobility in a sustainable way. The injection moulding company currently employs 147,000 people and operates 14 technical centres as well as production locations and customer service centres across 45 countries.

How Minebea Intec Combined Precise Weighing Results with a Flexible and Mobile Design

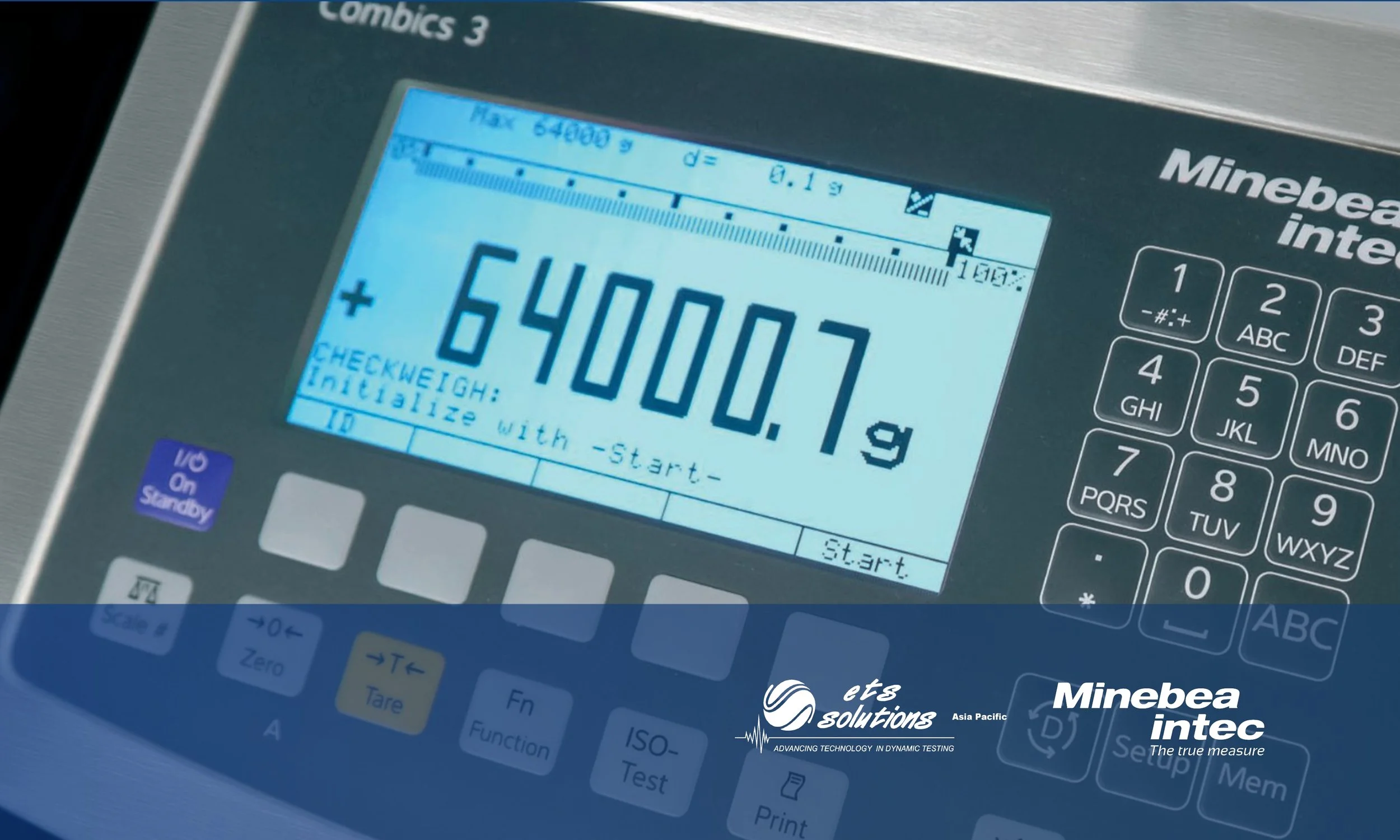

Mobile scales excel in industrial environments in which work processes require greater flexibility and better use of space. A high-resolution industrial scale was combined with an indicator to create a flexible and precise weighing solution. A high-resolution platform for precise results was combined with an indicator for accurate counting and weighing in a clean room. The weighing solution was combined with wheels and batteries for mobile and flexible operation.

High-speed weighing in the smallest of spaces: checkweigher exceeds all requirements

The company has been a Minebea Intec customer for many years and was already using Vistus metal detectors to check various products for metal contamination. Now, the customer needed a high-speed checkweigher that was MID approved and could deliver speeds of up to 800 products per minute. Minebea Intec met this challenge by developing a customer-specific version of the checkweigher Flexus Combi. The specially developed checkweigher is a dual-track solution, in which the two tracks support speeds of up to 400 pieces per minute.

Vistus brings better sensitivity and space-saving metal detection solution for dried and fresh fruits

Due to an increased production volume, the Pacific Nut Company Chile S.A. expanded its production and packaging lines in terms of weighing, sealing, and box packaging. In the process, also the critical point of metal detection needed improvement. The former metal detector, checking packed boxes of up to 10 kg dried raisins, had shown a lack of detection sensitivity. In addition, thermal fluctuations and changing humidity conditions had led to false rejections. Facing limited space due to the newly expanded production line the customer contacted the certified Minebea Intec Partner Antalis Abitek.

Mobile Weighing For Clean Rooms

Boehringer Ingelheim relies on UDF vessels, which are put to use under cleanroom conditions – both after ultrafiltration and before the product filling stage. The pharmaceutical company ordered a mobile weighing solution for a 50 l ultrafiltration vessel weighing 320 kg in total. The extended remit required the solution to be resistant to cleaning products, be able to withstand transportation stresses and to include the option of connecting the weighing station to the existing PLC.

High-speed check weighing: Minebea Intec technology helps to keep up the pace in the packaging line

Narrow packs of sweets with an extremely small supporting surface had to be checked for their integrity, contamination and reliably removed at high speed from the product flow where necessary. The weighing solution had to have a MID approval for high speeds. The packs are fed onto and discharged from specially-designed conveyor belts, weighed, inspected, and ejected from the product flow were necessary at a throughput of 430 pieces per minute.

High Precision, Hygienic Design Weighing Solution Impresses the Pharmatec GmbH

High-precision and reliable weighing technology was an essential prerequisite to ensure all requirements were met. Even the smallest deviations can lead to potentially harmful consequences in the production of medicines. Pharmatec, therefore, decided on the weighing module Novego from Minebea Intec.

Weigh price labeller WPL-S: Meat company opts for the superior quality of Minebea Intec’s technologies and customer service

Meat producers R&J updated their weigh price labeller for a more superior product; the Minebea Intec WPL-S which has increased productivity levels and reduced cleaning time of machinery within their factory. R&J Yorkshire’s Finest Farmers and Butchers was founded in 1978 by Jo and Robert Atkinson. Inspired to build on the solid foundations of their successful livestock business, they began to supply meat directly to friends, neighbours and local families. Since then, the company has grown steadily. In 2017 they doubled the size of their factory to meet the growing demand for Yorkshire’s Finest products.

How To Choose The Right Industrial Floor Scale

Industrial floor scales are characterised by extremely large platforms and are suitable for all sectors in which heavy and bulky loads have to be weighed. In the shape of the floor scales Combics® and Midrics®, along with the flat-bed scale IF and the pallet scale IU, Minebea Intec offers a raft of weighing solutions – including for potentially explosive environments.

Floor Scales - Flat-bed scale IF For precise weighing results and simple loading and unloading

The Right Weighing Scale for Food Industry - Part 2

Minebea Intec has decades of experience in the development and manufacturing of innovative quality control equipment for weighing and foreign body detection purposes. A great deal of this experience has been in food and beverage manufacturing applications, where quality control is of great importance for the vital role it plays in safeguarding many of the key interests of manufacturers and consumers – such as food safety, quality and cost-effectiveness.

The Right Weighing Scale for Food Industry - Part 1

The food industry is quite complex with several steps involved in harvesting the raw ingredients, processing them, and selling them in stores. Weighing scales are used in virtually every step from farm to table, serving a variety of purposes for the multiple applications in the food chain. Minebea Intec’s extensive range of high-tech equipment for weighing, counting and batching raw materials and finished products, as well as for foreign body detection etc., is ideally suited to the food and beverage manufacturing industry, and can help ensure that such objectives are met – always.

What Are Industrial Weighing Used For?

Generally, the industrial weighing scale, a measuring instrument, is integrated into the production process at a specific point where it is intended to fulfil a certain purpose. The primary use of a scale is to weigh things. For this purpose, an appropriate vessel or a moveable container is placed or driven onto the scale, the scale is tared, and the solid or liquid sample is placed into the vessel or container according to the specifications.