Vibration measurement is complex because of its many components: displacement, velocity, acceleration, and frequencies. Vibration measurement is an effective, non-intrusive method to monitor machine condition during start-ups, shutdowns and normal operation. Regular vibration monitoring can detect in a power plant shaft lines, deteriorations and defects of a number of various structural mechanical conditions, for example cracks, bearing faults, coupling damage, imbalance as well as interruptions in the electric grid.

Gas Turbine Vibration Monitoring

Vibration measurements are commonly considered to be a sound indicator of a machine’s overall health state (global monitoring).The general principle behind using vibration data is that when faults start to develop, the system dynamics change, which results in different vibration patterns from those observed at the healthy state of the system monitored.

Vibration Analysis on a conveyor unit

Belt conveyors are an integrated transmission and carrying mechanism with length sometimes extending several thousand meters. In traditional design and analysis of belt conveyors, vibration and impact are usually ignored and only static design is considered. However, to ensure the safety of conveyor operation for this restricted analysis, designers must increase the safety factor, which increases production costs. Many research groups have conducted dynamic analysis of large belt conveyors to reduce production cost and optimize conveyor performance. The conveyor belt was first modeled as an elastic body and then a viscoelastic body to incorporate viscoelastic characteristics of belt cover layer.

Electronic Components Reliability Testing

If your company makes planes, trains, automobiles, medical devices, computers, and communication systems, or you are a large electronic device supplier, the reliability of your products in the field is crucial to your business success. The growing market for electric and hybrid vehicles is increasing the pressure on life-time performance of the devices that power them.

Torsional Vibration Analysis

Torsional vibration measurements allow engineers to better understand the dynamics of their rotating equipment, enabling them to troubleshoot and/or validate performance. With a better understanding of the reasons and methods to measure torsional vibration, the right instrumentation, and a helpful partner, you will become better positioned to make the decisions you need to decrease downtime and increase productivity.

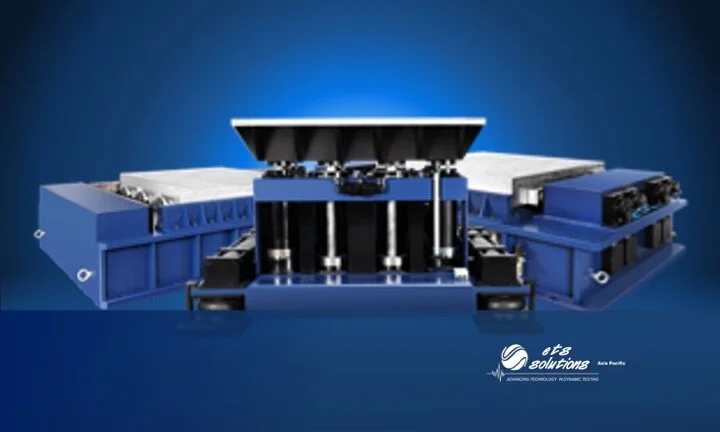

Motion Simulation and Testing

A motion platform simulator is a mechanism that creates the feelings of being in a real motion environment. In a simulator, the movement is synchronized with a visual display of the outside world scene. An important feature of a motion platform simulator consists of its degrees of freedom (DOF), the number and types of moves that an object can make inside a given space.

What is Industry 4.0 in terms of Manufacturing, the innovations and trends

By its nature, an Industry 4.0 implementation will be incremental, not big bang. Manufacturing will still need people and centralized information applications in addition to the new IIoT data for the next several decades. That’s where the systems that manage all that data, and the people, processes, products and machines that generate it – manufacturing operations management (MOM), or the next evolution of manufacturing execution systems (MES) – will play a critical role.

Condition Monitoring Techniques, Applications, and Tools

Condition monitoring starts with basic inspections. Small changes, like abnormal heat or pressure, strange sounds, excessive vibration, or a different smell, are often signs that something is going haywire. There are several machine condition monitoring techniques that are used for the assessment of machine conditions.

Types of Vibration Control

Vibration Research designs and manufactures leading edge vibration control systems for all brands of electrodynamic and servohydraulic shakers, as well as portable dynamic signal analyzers. Vibration control systems include hardware vibration controllers and the vibration control software, providing a multi-point control of complex structures, all with an intuitive user interface and easy setup.

Tips or guidance to consider before buying and operating a vibration shaker

SRS - Shock Response Spectrum

Accelerometer

An accelerometer is a device that measures the vibration, or acceleration of motion of a structure. They measure in meters per second squared (m/s2) or in G-forces (g). The force caused by vibration or an acceleration (change in motion) causes the mass to "squeeze" the piezoelectric material which produces an electrical charge that is proportional to the force exerted upon it. Since the charge is proportional to the force, and the mass is a constant, then the charge is also proportional to the acceleration. Accelerometers are useful for sensing vibrations in systems or for orientation applications.

What is actually a vibration sensor?

Battery Temperature Test Chamber

Different environmental conditions such as extreme heat, extreme cold, moisture or other variables can influence a device failure in various ways. In today’s world, we all expect fault-free products and uninterrupted operations and services and in order to guarantee 100% performance, manufacturers from various industries must conduct environmental simulation tests of their products.

Vibration Analysis

Vibration analysis is the most prevalent method used to monitor the levels and patterns of vibration signals within a component, machinery or structure, in order to detect abnormal vibration events and then using that information to analyse and evaluate the overall condition of the component, machinery or structure. In short, vibration analysis helps you monitor and detect issues using vibration data

How to choose the right packaging testing methods – Shock Testing

If you’re designing the packaging for a new product or a rebranding, you probably want to know how safe your goods will be and how customers will react to your packaging before you invest in a final design. With packaging testing, you can both satisfy consumer sentiment and choose the right packaging design for your product from the safety point of view.

What is an EMC or Anechoic Chamber and How is Working?

An electromagnetic compatibility (EMC) or anechoic chamber is a highly specialized piece of test equipment used in the testing of electronic devices against regulatory standards concerning both radiated and conducted radio frequency (RF) emissions and immunity. EMC or anechoic chambers are designed to create an enclosure with an extremely high level of shielding attenuation against electromagnetic interference.

Vibration Testing on Shakers

Vibration Testing is one such environmental test critical to the design process. All closed-loop vibration tests, consists of four main components: a vibration controller, an amplifier, a shaker, and a feedback sensor, together, these four components make up a vibration testing system. ETS Solutions Asia instruments vibration controllers control electrodynamic and hydraulic shakers from tabletop to warehouse size systems.

Condition Monitoring, What is it?

Condition monitoring is the activity of periodically checking equipment, with the aim that the equipment is in a healthy condition so that the equipment can work according to its function. Adopting proactive predictive maintenance techniques is much more than just good plant management, it is good business. Anticipating machine failures before they occur, allows you to catalyze improvements that create positive ripple effects for the entire enterprise.

Noise and Vibration Monitoring Guidelines

Noise and vibration are both dynamic processes and have a close physical relationship. Vibrating systems make noise, and noise makes structural systems vibrate. Both noise and vibration are adversely affecting people and if sufficiently intense, both noise and vibration can permanently hurt people. At the same time, also structural systems, if excited by excessive noise and vibration over sufficient periods of time, can fatigue and fail.