LS SERIES

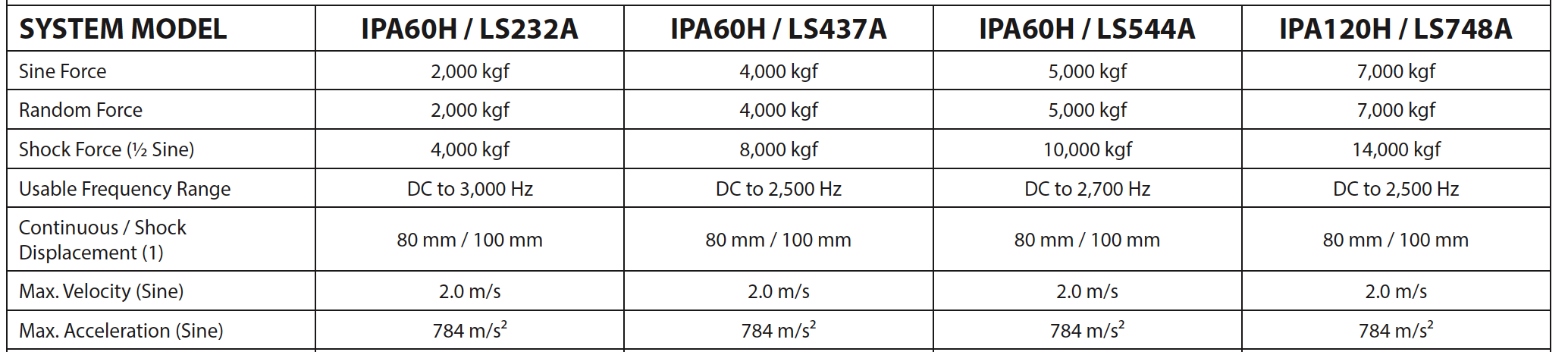

Vibration System Force Rating from 2,000 kgf to 7,000 kgf

Ideal for test applications such as packaging testing and vehicle testing.

The Long-Stroke (LS) Series vibration testing systems are designed for long-stroke displacement test requirements normally performed by hydraulic shakers. Compared to a hydraulic shaker where maximum test frequency is typically around 400 Hz, the Long-Stroke Series is capable to testing up to 2,700 Hz with maximum acceleration of 100g (bare table) bounded by 2.0 m/s maximum velocity. This provides users time and cost savings for wide test requirements.

BENEFITS

Simple system operation

Intelligent PLC control and monitoring system

High-energy conversion efficiency (greater than 90%)

Reasonably priced optimal performance system for major test standards

Compact shaker and amplifier size saving valuable floor space

Shaker air-cooled by rugged outdoor blower for continuous long-period operation

Air cooled amplifier for safe and reliable operation

Ethernet port available for data exchange

All-encompassing fuse protection designed for high current system components

Detailed scope of system interlock protections

Complies with USA, European and international safety and EMC regulations

Compatible with all vibration controllers

Remote control panel via Ethernet cable connections

Low-profile body design ready for chamber integration

Integration with unibase or standalone slip table

Simple initial self-system setup

Interactive diagnostic “System Status” displayed on touch screen

Easy maintenance and rapid servicing

Worldwide spare parts support

FEATURES

THE PERFORMANCE

Specimen payload up to 1,000 kg

Excellent random performance meeting ISO standard with 3 sigma peak current rating

Armature diameters range from 320 mm to 480 mm

Up to 100 mm continuous displacement

Test frequency up to 2,700 Hz

THE SHAKER

Rugged trunnion design with bearing guidance

Air bag isolator built-in reducing dynamic floor stress

Dual layer reinforced armature for high acceleration performance

Roller bearing flexure with load support bearing suspension system achieving high cross-axial stiffness

THE AMPLIFIER

Integrated with new Intelligent Power Amplifier

New design with High Speed IGBT technology

Compact sized power module with large output (60 kVA each)

High modulation switching frequency

High signal to noise ratio

Dynamic fault current error control protection

Complete digital control

THE ACCESSORIES

Air load support for armature centering

Dynamic and static armature centering available

Geared aided rotation for uni-base slip table

Thermal barrier for combined climatic chamber test available

Remote control capabilities available